Hinged glass door (tempered safety glass)3D 672

Art. No. 672012225

clear

matt

596.59 €

MSRP (based on german VAT)*

3D 672

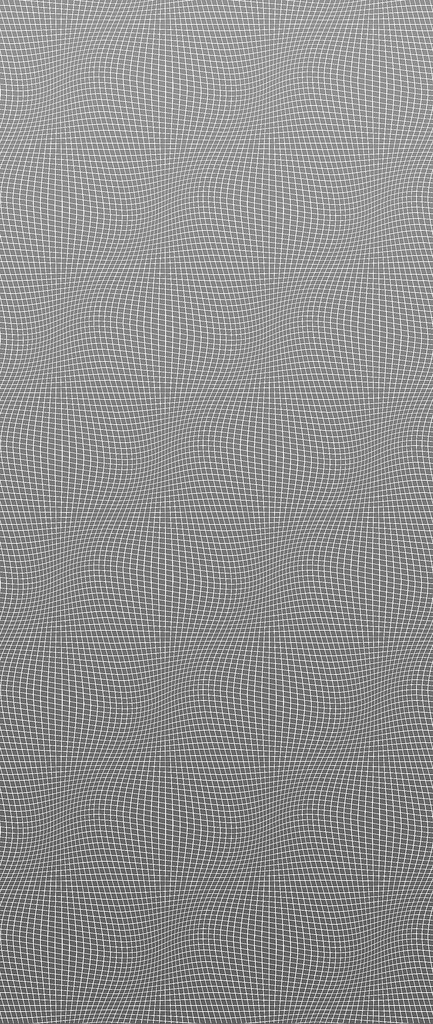

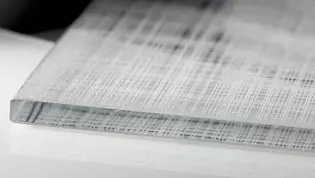

Mulridimensional

Fine, overlapping lines lend the glass door a dynamic depth effect. We also laser these motifs onto PURE WHITE by GRIFFWERK white glass, so that the decors are brilliantly accentuated. All designs are suitable for hinged and sliding door systems. Symmetrically mirrored, the three-dimensional effect looks particularly spectacular on double-leaf systems.

Supplied with

1x glass revolving door

Alternative products

Accessories

Even more security for your glass door?

Both toughened safety glass (TSG) and laminated safety glass (LSG) are classified as safety glass. The main difference between toughened safety glass and laminated safety glass is that the shards of a laminated safety glass pane, in case of breakage, stick to an internal film, which minimises the risk of injury.

Advantages

- Height safety

- More sound insulation

- Ideal for XL formats

- Matting possible on both sides

- Highest Opacity possible

- More aesthetics

- Rich sound when closing

Glass doors

Glass revolving doors are becoming more and more trendy and are the stars among doors: they open up rooms and perspectives. Glass doors provide living rooms with light, allow wide lines of sight and make living areas appear friendlier, brighter and altogether larger. A revolving door made of glass is the optimal alternative to a revolving door made of wood.

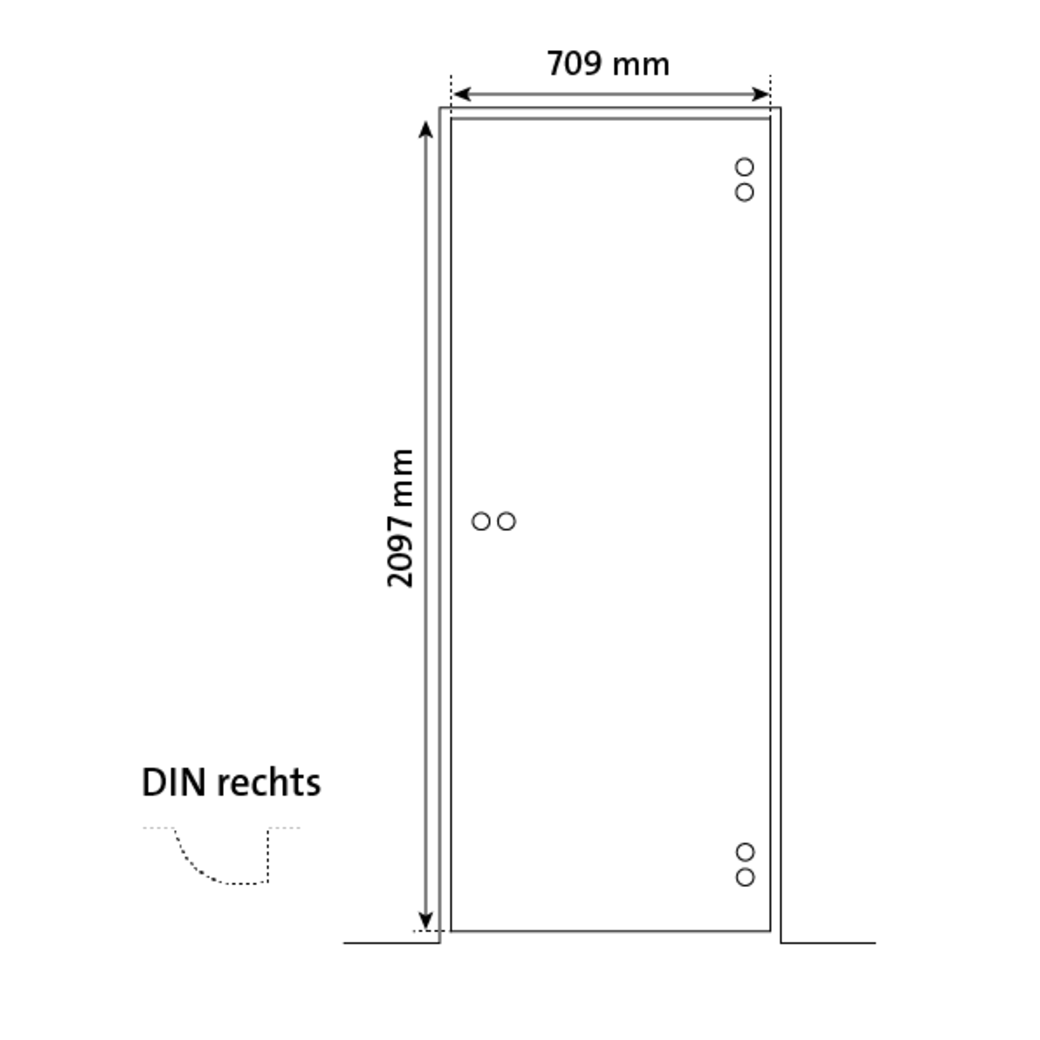

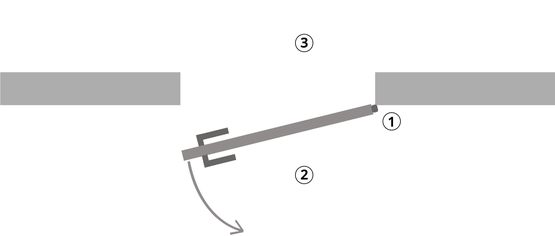

What is DIN Direction Right for Doors?

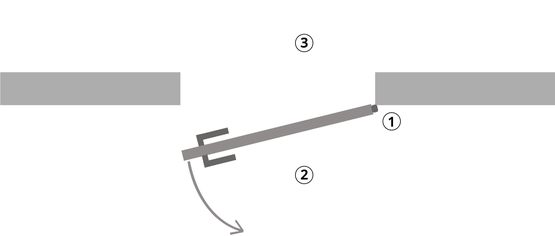

The DIN direction indicates the direction in which a door opens. Your door is DIN right when you stand in front of it. This opens towards you. The side on which the hinges (1) of the Hinged door are located is called the hinge side (2) and is on the right-hand side. You are standing in front of a DIN R Door! The opposite hinge side (3) is the opposite side of the Door.

If the hinges are on the right, it is a DIN right-hand door.

What is the DIN direction for glass doors?

The DIN direction indicates in which direction a door opens. Do you want to find out which DIN direction is the right one for you? Then imagine you are standing in front of the door. It opens towards you. The side on which the hinges of the Hinged door are located - also called the hinge side - determines the DIN direction.

If the hinges are on the right, it is a DIN right-hand door.

If the hinges are on the left, your door is a DIN left door.

What is the tape side and the tape opposite side?

Door hinges connect a door to the door frame and at the same time allow it to rotate. The hinge side (2) is the side on which the door hinges (1) are located. The opposite hinge side (3) refers to the side opposite the door hinges.

Pure White

White glass has a particularly noble effect and is characterised by a bright lighting effect in modern rooms. The green or grey tinge present in the product range is reduced to a minimum here. With PURE WHITE from Griffwerk, colour-neutral and flexible room design is guaranteed. White tones and daylight are expressed in a particularly natural way.

Clear or rather matt glass?

Natural daylight and bright rooms - that is the advantage that clear glass brings. In contrast to matt glass surfaces, an open view with natural light incidence is made possible. Laser motifs look brilliant on clear glass doors.

What is Laser One Side?

- ONE SIDE means one-sided processing of the all-glass door with laser technology.

- Here a clear glass blank is used

- The transparency of the door is maintained

- Depending on the incidence of light, the lasered area scores with its high luminosity

- One Side is very noble and stylish

Fascination Laser Technology

Special lasers engrave filigree Lines into the glass surface. Point by point and precisely controllable, detailed images, patterns and lettering as well as finely graduated gradients can be transferred to the Glass. Our laser places microscopically small pixels next to each other for this purpose, so that photorealistic results can be achieved. The recessed engravings change the reflection of light. Lasered Glass doors remain transparent. The TWO SIDES option with satin finish on the back provides more privacy.

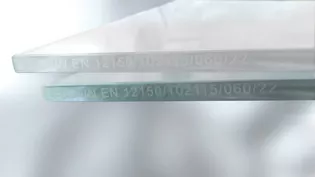

Laser doors from Griffwerk meet ESG standard

GRIFFWERK glass doors made of toughened safety glass ("ESG") meet all requirements for applied laser technology according to the German Institute for Building Technology (DIBT). Since then, GRIFFWERK has been allowed to mark all glass doors with the ESG test stamp, which complies with the DIN EN 12150 standard. The stamp is placed inconspicuously on the hinge side of the glass edge. We are proud to be able to offer you tested safety.

How do I clean a revolving glass door?

To clean the surfaces of interior revolving glass doors, warm water is sufficient. Please use a sponge or a soft, lint-free cloth for this purpose. Clean over a large area and not selectively.

If any remaining dirt such as fingerprints is still visible on the revolving door, you can also use commercially available glass cleaners (foam cleaners). Please do not use any abrasive, corrosive, acidic or alkaline cleaning agents. They attack the glass surface and can thus be the cause of scratches. You can wipe excess water dry with a microfibre cloth. If glass is in contact with water for a longer period of time, stubborn limescale residues can form.

With laminated glass doors, make sure that the edge seal does not come into contact with water, otherwise moisture and the cleaning agent can penetrate the laminate.

Attention

Please do not use any scratching tools, razor blades or scrapers. They can leave visible and irreparable scratch marks on the surface.

Particular attention should be paid to this with satinised and lasered surfaces

To avoid abrasion of the surface structure, do not apply too much pressure. To avoid the so-called cloud formation, rub your glass door dry over a large area with a microfibre cloth. Do not use paper or cellulose cloths. They cause too much abrasion.