Sliding doors from Griffwerk

From sliding door systems to handles, sliding door leaves and different designs: you can find all of this at Griffwerk.

Why glass sliding doors?

- They allow natural daylight into every living area and promote healthy living

- Rooms appear larger thanks to transparent room transitions

- Small niches can be better utilized - for example as a walk-in closet or storage space

- More daylight saves energy - you compensate less with artificial lamp light

- Sound-absorbing properties contribute to peace and privacy

- Elegant aesthetics and timeless appearance suit all furnishing styles

- Barrier-free access without a threshold allows easy movement between rooms

- Glass is a sustainable material that is recyclable and has environmentally friendly properties

- They create a seamless connection between indoor and outdoor areas and extend the living space

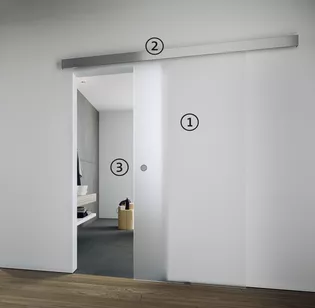

How do sliding glass doors work?

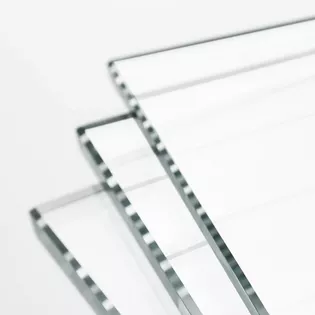

1. sliding door leaf:

The sliding door leaf is the central element of a sliding glass door. It is made of tempered safety glass, available in a variety of finishes. Clear or frosted variants offer different degrees of transparency. Additionally, the door panel can be customized with different decors, patterns or even colors. This can affect both privacy and the overall aesthetic appearance of the interior.

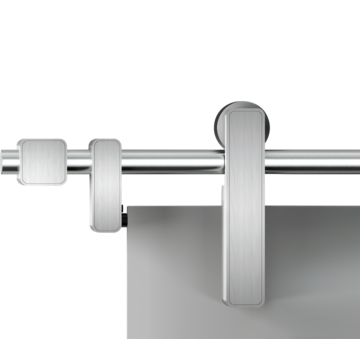

2. sliding door track:

The track holds the structure and allows the glass door to move. This rail can be integrated in several ways: Either minimalist concealed or visible as a decorative element. It is usually made of aluminum or stainless steel to ensure a solid load-bearing capacity. The rail with integrated runners allows the sliding door leaf to slide smoothly and contributes to the overall functionality of the structure.

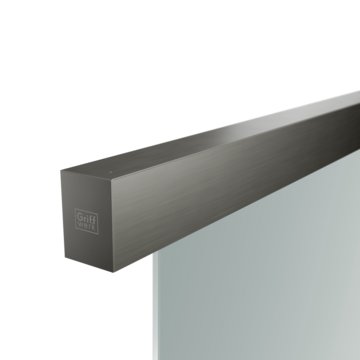

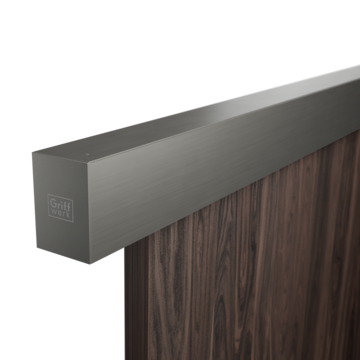

3. sliding door handle:

Whether it is a handle bar or a discreet handle shell, the door handle allows the sliding door to open and close effortlessly. This detail contributes to the overall appearance of the glass door and can also affect the overall look of the room.

Sliding door systems

All sliding door fittings from a single source: track, trolley, soft-close mechanism - for ceiling or wall mounting.

Bar handles and grip shells

Find a handle shell or Bar handle that fits perfectly with your interior style: From Loft to Hygge.

Sliding door panels

Flint glass, gray glass or green glass - whether matt, transparent or decorated: Here you will find the right door leaf for your sliding glass door.

Glass sliding doors are good?

Yes, because they have numerous advantages. Sliding glass doors ...

- let daylight into every room.

- do not have a swing area and therefore save space

- are a stylish and elegant way of separating or connecting rooms

- are ideal for barrier-free living.

- do not do not close in draughts - for relaxed ventilation

- allow larger dimensions than hinged doors

- can disappear behind furniture

- create new practical spaces - from the study to the walk-in closet

Stylish design - Perfect technology

Unmistakable design meets technology of the highest quality. Open Glass sliding door systems exude a touch of loft character and, especially as double-leaf variants, look like spacious portals. Closed models, on the other hand, are Clear-cut and discreet. The mechanism is concealed inside. They are available in Stainless steel or Aluminium and with a wide Width of variants.

The new Black

We have equipped the PLANEO 120 sliding door fitting with additional room solution options. In the range are also available skylights, side elements and much more. In addition, PLANEO 120 is also available in "Graphite black" finish. All variants are available with Soft-Close. This means that the Glass sliding door does not hit, but is gently retracted into the locking position: little things that simply offer more living comfort. All models can also be realized room-high.

Space-saving miracle

Cleverly thought-out solutions allow rooms to be adapted to individual living requirements without the need for additional walls. Apartments can be visually enlarged by means of long sight lines. The best way to do this is with glass sliding doors, because they open up rooms - unlike opaque wooden sliding doors, for example. Glass sliding doors, for example, open up a view of the living area from the hallway. And the small side room facing the backyard benefits from daylight from the sunny south side.

For example, consider the possibility of connecting the dining room with the living room or kitchen by replacing the old Wooden doors with light-filled Glass sliding doors. Even in old apartments, you can go for an open floor plan and let the daylight from the sunny south side flow into neighboring rooms.

Sliding door complete set: tailored to your needs

At GRIFFWERK, you can easily put together your individual complete sliding door set with the help of our experts.

If you have particularly limited space available, a sliding glass door is the perfect choice as, unlike hinged doors, it does not need to swing into the room. The sliding glass door runs along the wall to save space. Even complicated installation situations can be easily mastered with sliding glass doors, because at GRIFFWERK you can find almost any special dimensions you require online. Our specialist retail partners will be happy to help you determine the right dimensions - conveniently for your selected model or desired model. You can also select the right sliding door fitting there - also as a sliding door fitting set.

Glass sliding door set: But please room high!

If you can, you can afford room height; the higher, the better. It's nice when the doors also use the entire height. Full-height all-glass doors make the most impressive impression. All our models are therefore available in custom sizes. Your specialist dealer will advise you on the right dimensions and fittings. They will also know which door weights and hinges are suitable for your selection, as large doors weigh more - and should not sag later. High-quality equipment details such as drill hole adapters in the hinges for hinged doors stabilize large doors. At GRIFFWERK, the matching adapters are available with the hinged door fittings - simply research online on our website, find a dealer, done.

More harmony with skylights

Those who do not want continuous door heights, choose a solution with skylights. Skylights are transparent areas above the door, usually divided by a cross frame. The standard dimensions are thereby visually opened to the top. This is a trick to include the design reference to other doors with normal height.

Optimize floor plans

Glass doors open up rooms, allow wide views and make living areas look brighter and larger. They are therefore ideal for changing floor plans during renovations, for example. In new buildings, on the other hand, floor plans that connect different functional areas - such as the entrance and living area or kitchen and dining room - are gaining ground. Interior doors made of glass then create room boundaries that act as a vestibule or provide privacy. White, Satin frosted glass or frosted glass provide maximum brightness and a spacious living feeling.

The advantages of sliding glass doors

Design your rooms more efficiently and create a bright living space. Here are some tips on how to optimize a floor plan with sliding glass doors:

- Improved lighting conditions in all rooms: With glass doors, daylight from surrounding windows also enters adjacent rooms.

- Connecting indoor and outdoor areas: A sliding door offers the ideal opportunity to connect the interior with the exterior. Ideally, you should place them opposite terraces, balconies or the garden to create a smooth transition between indoors and outdoors.

- Increase the appearance of space: Sliding glass doors can visually enlarge the space by creating a transparent barrier between different areas. This is particularly useful in small apartments.

- Separate rooms: Use sliding glass doors to discreetly separate areas in an open floor plan without compromising the visual connection.

- Room division: Sliding glass doors can be used to divide a large room into smaller, more functional areas. This can be helpful in homes, offices or even commercial establishments such as restaurants.

- Accentuation: A sliding door can serve as a design element. Choose frames, handles and embellishments that match the style of the room.

- Optimize the furniture layout: Plan the layout of the room with the sliding door movement in mind. Make sure that the placement of the furniture does not hinder the movement of the door.

- Privacy: Consider how much privacy you want in certain areas. Options such as tinted glass, frosted glass or opaque film, can ensure privacy without compromising light transmission.

- Maintenance and care: Remember that glass surfaces can show fingerprints and dirt. Keep sliding glass doors clean to maintain their transparency and attractiveness.

- Safety: Pay attention to the safety of sliding glass doors, especially if they are large. Go for toughened safety glass and make sure that the sliding mechanisms work properly.

Sliding door: Perfect for the home office

Even in smaller apartments, you can transform previously unused adjoining rooms into attractive, light-flooded workrooms with the help of glass room doors. With a glass sliding door, you can discreetly separate your home office from the rest of the living area. You decide how much privacy and sound protection you need:

- Opaque models such as Piano White offer maximum privacy.

- Translucent glass also provides a high level of privacy, but allows light to pass through.

- If you like a spacious loft character, opt for more transparency and double-leaf doors.

Wood room doors can be easily replaced with a Glass door. Sliding doors can even be installed over existing frames. By default, your Glass sliding door is made of toughened safety glass (tempered safety glass). On request, it can also be made with laminated safety glass (Laminated glass glass).

Room optimization with glass sliding doors

Sliding doors with plain text

This turns the glass door into a poetic entrance: Laser technology can be used to engrave texts or typographic decorations on Glass sliding doors. The motifs on gray glass are particularly fascinating. The white tone of the engraved Font stands out well against the gray tone of the glass material. You can also combine lettering motifs with green or white PURE WHITE by GRIFFWERK glass.

Simply choose your favorite motif or write your own text. Whether your philosophy of life, a meaningful date or a personal quote: your door becomes a canvas. Personalize your business premises or waiting room in your individual corporate design. Thanks to laser technology, even small quantities and individual designs are possible.

Sliding doors: FAQ

What is the cost of a sliding door?

The price of a sliding door depends on how big it is, whether it is single or double-leaf and what glass is used. A single-wing door in the simplest version can be obtained from about 100 euros glass + 250 euros hardware, whereas a double-wing sliding door with digital printing decoration can sometimes cost more than 1,000 euros.

How tight are sliding doors?

Sound as well as kitchen odours, water vapour and draughts are kept out by the tightly closing PLANEO AIR SILENT sliding door system from GRIFFWERK. The seal is made possible by laterally attached rubber lips and a floor brush. Both elements are integrated into the surrounding aluminium profile and blend into the purist design. The door reveal remains unchanged. PLANEO AIR SILENT is comparable to a wooden door in terms of sound insulation.

For which rooms is a Sliding door suitable?

Sliding doors are particularly suitable for rooms with limited space, such as small apartments or offices, and for areas where a seamless transition between indoor and outdoor areas is desired, such as terraces or balconies. They are also a popular choice for wardrobes, bathrooms, kitchens and as room dividers in large rooms.

Who installs a sliding door?

You can install sliding doors yourself. We tell you how to do this in the section "How are sliding doors installed? Alternatively, you can also commission a specialist with the installation. Dealers who sell Griffwerk products often offer an installation service. The specialist will then come to your home and professionally install the sliding door for you. If, despite careful work, faults occur, there is usually a guarantee that these will be rectified as quickly as possible, free of charge. The installation service is a quick way to achieve the perfect sliding door, especially for physically impaired people or people who are not very skilled.

What material for sliding door?

Sliding doors are usually made of glass, wood, plastic, metal or mixtures of these materials. Which door material is most suitable for the sliding door is determined by the intended use. The material ultimately determines essential door properties such as weight, light transmission, sound insulation, thermal insulation or burglar resistance.

Where can I find the right sliding door?

Whether clear glass or float glass, toughened safety glass or laminated safety glass - at GRIFFWERK we manufacture individual sliding doors for specialist shops and private individuals. Your specialist dealer is sure to have GRIFFWERK products in stock. You can find out more about our wide range of models on our website. If you have any individual questions, your specialist dealer will be happy to advise you. https://www.griffwerk.de/en/store-locator/

What is a Sliding door?

A Sliding door is a door that is opened or closed by sliding sideways along a track or guide, instead of rotating around a vertical axis like a conventional swing door. Sliding doors save space as they do not require any pivoting area.

What is the difference between hanging and standing Glass sliding doors?

Hanging and standing Sliding doors made of Glass differ mainly in the way of installation and operation. Here are the main differences:

- Installation:

- Hanging Glass sliding doors: this type of sliding door is suspended from the top. The Sliding door runs along the ceiling in a track system and is supported by Rolls attached to the top edge of the door. This allows the door to slide smoothly and requires None rails on the Floor.

- Standing Glass sliding doors: these doors run on rails that are mounted to the Floor. The door moves along these rails and is usually supported by Rolls on the Floor of the door. Compared to hanging doors, standing Glass sliding doors require a rail on the Floor.

- Space Requirements:

- Hanging Glass sliding doors: since they require None rail on the Floor, hanging Glass sliding doors are usually more space efficient. They are well suited for rooms where floor space needs to be kept clear, such as when a uniform floor covering is desired.

- Standing Glass sliding doors: these doors require a floor track that takes up some floor space. In some cases, this can impact the design of the room.

- Aesthetics and Design:

- Hanging Glass sliding doors: Because they do not require a floor track, hanging sliding doors can have a sleeker and more minimalist appearance. Suspension from the ceiling can also provide an elegant aesthetic.

- Standing Glass sliding doors: because of the visible bottom track, these doors can appear a bit more massive. However, they still offer a solid and traditional look.

- Installation and Customization:

- Hanging Glass sliding doors: installation requires the addition of a sturdy ceiling mount and proper alignment of the Rolls to ensure smooth gliding. Adjustments may be required to ensure the door hangs level.

- Standing Glass sliding doors: installation requires proper insertion of the Floor track and adjustment of the Rolls at the Floor of the door. Adjustments are also needed here to ensure the door can be moved easily without jamming.

Ultimately, the choice between hanging and standing Glass sliding doors depends on individual preferences, available space and desired design. Each option has its own advantages and disadvantages, which should be considered when making a decision.

What are the advantages of sliding doors?

One advantage of sliding doors is that they save space since they do not have to swing in or out of the room. They are also easy to open and close, making them well-suited for people with mobility issues or for use in tight spaces. Sliding doors can also help reduce a building's energy consumption by retaining heat in the winter and preventing cool drafts in the summer.

Which sliding door is the trend?

There are essentially seven trends for the coming years:

1. the sliding door as a room divider to divide up large rooms at short notice.

2. making small rooms or niches usable thanks to sliding doors - for example as a home office or guest toilet.

3. walk-in closets: niches can easily be turned into walk-in closets thanks to sliding doors.

4. Small rooms appear larger thanks to sliding glass doors. This use will continue to increase.

5. loft style is increasingly finding its way into homes - even through small things like black hardware for a sliding glass door.

6. sliding track systems for the sliding door - especially those that disappear into the wall - are particularly trendy.

7. a frosted sliding door or decorated with photo printing: also a trend for the next few years.

How do I lock sliding doors?

With the PLANEO SMART2LOCK locking system from Griffwerk integrated in the handle, sliding doors can be locked at the touch of a button. The locking technology is invisibly integrated into the handle bar and sliding system. An LED on the handle bar indicates inside and outside whether the door is locked.

What should I consider when choosing handles for Sliding doors?

When choosing Sliding door handles, there are several important aspects to consider to ensure that they are not only functional, but also aesthetically and ergonomically suitable. Here are some Spots you should consider:

- Functionality: the Sliding door handle should be easy to grip and operate. Not only should it feel good in your hand, but it should also provide adequate leverage to move the door panel effortlessly.

- Material and Quality: Sliding door handles are available in different materials such as Stainless steel, Aluminum, Plastic or Wood. Choose a high-quality material that is durable and sturdy to withstand daily use.

- Ergonomics: the handle should be designed to fit comfortably and securely in your hand. An ergonomic design allows for ease of use, especially if the door is used frequently.

- Style and aesthetics: the Sliding door handle contributes to the overall aesthetic of the room. Choose a handle that matches the style and decor of the room. There are a variety of designs, from modern and minimalist to traditional and decorative.

- Size and proportions: Make sure the handle is the right size and proportion so it doesn't look oversized or too small in relation to the size of the door.

- Mounting: consider how the handle will be mounted on the Sliding door. A handle can be mounted on the front or back of the door panel, depending on the desired aesthetic effect.

- Accessibility: if necessary, choose a Sliding door handle that is barrier-free and can be easily reached and operated by people with limited mobility.

- Durability and maintenance: consider the maintenance requirements of the material you choose. Some materials require more care than others to maintain their luster and quality over time.

- Price: Sliding door handles vary widely in price and quality. Set yourself a budget and look for a handle that meets both your needs and your budget.

- Additional features: Some Sliding door handles come with additional features like locking mechanisms or lock cases. If you need such features, make sure the handle meets those requirements.

- Installation: Make sure the handle is easy to install or can be properly installed by professionals to ensure safe use.

Remember that the Sliding door handle is not only a functional element, but also contributes to the aesthetics and usability of the room. It is important to make a careful selection to ensure that the handle meets the requirements and style of the project.

Sliding door leaves made of Glass: What do I need to consider?

For sliding glass door panels, it is critical to use tempered safety glass that meets stability and safety requirements. The thickness of the glass should be adequate to ensure sufficient strength. In addition, the installation should be done carefully to ensure the stability of the door leaf and minimize the risk of glass breakage. The size of the glass leaf should also be well matched to the Sliding door system to allow smooth opening and closing.

Are there lockable sliding doors?

Yes, sliding doors can be purchased as lockable and non-lockable variants. Compared to the ordinary revolving door, the bolt of the sliding door cannot engage directly with the striking plate of a normal frame. Since the movement is parallel to the wall, a hook or compass bolt lock must be fitted to the sliding door system. This engages in the door frame and makes the sliding door lockable. Sliding door systems in front of the wall require a stop post onto which the door leaf can run.

At GRIFFWERK we get around this problem with the PLANEO SMART2LOCK system. Invisible from the outside, the locking technology provides a secure lock.

Is a sliding door more expensive than a swing door?

Of course, there are both sliding and swing doors in all price segments. On average, sliding doors are somewhat more expensive than hinged doors because a different mechanism is required. However, the investment is usually worth it because sliding doors save a lot of space and open up rooms that would otherwise be unusable.

How do I determine the allowance of the sliding door?

Whether you use a folding rule or a laser measuring device - the most important thing is to always measure at several points. Especially in old buildings, ceilings, floors and walls are not always completely straight. For an accurate measurement, it is best to measure at the far left and far right from wall to wall at three points (bottom, middle, top) and at the very top and very bottom at three points from the ceiling to the finished floor. When ordering the sliding door, always use the smallest dimension. As a rule, all sliding doors can be subsequently adjusted in height by one to two millimeters.

Are sliding glass doors shatterproof?

Sliding glass doors are usually made of either single-pane safety glass or laminated safety glass (LSG), which is about 8 millimeters thick. This corresponds to a high level of break resistance. In the case of sliding glass doors made of toughened safety glass, only punctual, strong pressure loads can cause the glass to crack. The splinters are very small and blunt. In the case of laminated safety glass, it takes even more force for a pane to shatter - but the pane splinters then stick - to the adhesive film that holds the laminated panes together.

What are the types of a sliding door?

There are different types of sliding doors, such as rail sliding doors, flush sliding doors, and wall or ceiling sliding doors.

Are sliding glass doors modern?

Sliding glass doors are often used in modern interiors in such a way that they are a visual highlight: Thanks to laser engravings or similar discreet decorations. Thanks to their translucency, they create a warm feeling of space and make the room appear larger than it actually is.

How wide are sliding doors?

935mm x 2058mm x 8mm (width x height x depth). This is the typical standard size for sliding doors. Other standard dimensions are 1060x2085x8 mm and 935x2183x8 mm. Glass doors are also available in special sizes.

Why sliding doors?

Sliding glass doors let daylight into every room and save space at the same time. They are also wonderfully suitable as room dividers and optimal for barrier-free living.

What do sliding glass doors weigh?

The weight of a sliding glass door varies from door to door and depends on the dimensions and type of glass. We therefore have a few examples for you: Sliding doors measuring 935x2058x8mm (for example, our Lines Four 503 sliding glass door made of toughened safety glass) have a surface area of 1.94 m². This weighs around 39 kg. A wider sliding glass door (1060x2058x8mm) is slightly heavier at approx. 44 kg. Sliding doors for high rooms (935x2183x8mm) are in the middle at around 41 kg.

How to use sliding doors as room dividers?

Instead of permanently transforming a large room into several small ones by putting up a wall, sometimes a floor-to-ceiling sliding door is more suitable: it divides large rooms into smaller ones - temporarily or forever, but in any case without taking away light. How exactly to do this, read our blog.

Can sliding doors be retrofitted with a tight-closing system?

In principle, it is possible to retrofit a tight-closing system on sliding doors. There are ready-made sets with rubber bands to stick on. Of course, you can also ask a specialist for help. At Griffwerk, the sealing system is permanently built into the product. Therefore, retrofitting is not possible.

What has to be considered for fittings with clamp mounting?

LSG doors can be used for glass door systems with clamp mounting SENSA by GRIFFWERK. The inner foil is only slightly elastic. We nevertheless recommend readjusting the screws of the fixing after some time and later if necessary. Glass doors, like wooden doors, can adapt to changing room conditions and thus change. Please refer to the respective product data sheets for detailed information.

Which glass for sliding doors?

Toughened safety glass or laminated safety glass. The former is heat-treated glass with increased impact and shock resistance. In the event of breakage, small, blunt shards are produced.

If the sliding door is to be particularly robust, we recommend LSG PRIME DOORS. They consist of two thermally toughened safety glasses and an inner tear-resistant film. In the event of breakage, the shards adhere to this intermediate layer. In addition, LSG prime glass has sound-absorbing properties.

Sliding glass door - What do I need to consider?

Sliding glass doors widen any room due to their translucency. To maintain this effect for a long time, it is important that the glass is cleaned gently. The best way to do this is to use warm water, a sponge or a soft, lint-free cloth. Residues are best removed with an ordinary glass cleaner. More aggressive cleaning agents such as scouring agents should not be used. They can roughen the glass surface, causing scratches or even damaging the protective layer.

Professional tip: Cleaning large areas instead of specific spots prevents water spots and limescale residues.

Are sliding doors standardised?

The European standard DIN EN 1527:1998 specifies the basic criteria of building hardware and test methods and classes of the respective types of sliding doors - its exact name is: "Locks and building hardware - Hardware for sliding and folding doors - Requirements and test methods".

The standard differentiates sliding doors according to safety requirements, weight, handling, service life and opening direction.

Where to buy sliding doors?

High-quality sliding doors are best purchased from a specialist dealer. You can also purchase sliding doors from GRIFFWERK from our contractual partners in the online store.

How well do sliding doors close?

GRIFFWERK sliding doors with the PLANEO AIR SILENT system close almost airtight. This prevents water vapor or strong smells - e.g. after cooking - from entering the next room. You don't have to worry about drafts either. In addition, sliding doors of this design offer good protection against noise - comparable to the soundproofing of a wooden door.

Can I install a sliding door myself?

A sliding door running in front of the wall, you can install yourself using the supplied installation instructions. In most cases, the installation requires two people. If you want to install a sliding door that runs in the wall and need to install the necessary drywall or box system, it is better to hire a professional - unless you are well versed in building things.

Does a sliding door have a frame?

Frames are not required for a sliding door. If frames are nevertheless installed, the distance between the sliding door and the wall can be increased by using a spacer profile, so that the door can easily run in front of the frame.

How are sliding doors installed?

- Observe the material of the wall for the selection of the appropriate drill and dowel.

- Align the running rail on the wall with the help of a spirit level. Mark the predefined fastening holes of the running rail on the wall. Drill the indicated fastening points and mount the rail.

- Mark the floor guide on the floor according to the opening direction of the sliding door, pre-drill and install. If the floor is smooth, the floor guide can also be glued to the floor with the enclosed adhesive strip.

- Slide the end stopper and soft pull into the sliding door rail. On the handle side, fix flush with the edge of the running rail with the appropriate torque. Do not yet fix the mounting parts on the other side.

- Thoroughly clean the glass door leaf on the upper glass door surface before attaching the carriage. Adjust the runner for the corresponding glass thickness and mount the activator.

- Fix the trolley in the appropriate position on the glass door. Loosen the safety screw and slide it downwards.

- Hang the glass door leaf. Use the adjustment screws to align the glass door. Slide the glass door into the open position and lock the rear stopper and soft-close mechanism in this position.

- Adjust the safety catch. If necessary, adjust the activator. Fit the cover for the sliding door rail and fix it in place with grub screws. Fit end caps.

- Stick the handle shell or handle bar onto the glass door using the SENSA adhesive technique. If necessary, use a template for application.

Can I replace an existing swing door with a sliding door?

Yes. If you choose a sliding door system that runs in front of the wall, such as R8 or one from Griffwerk's Planeo line, you can even install the sliding door over the old door frame, depending on your taste.

If you want a sliding door that disappears into the wall, you will need to create a cavity in front of the existing wall using drywall or a built-in box system, where the door can disappear.

How soundproof are sliding doors?

The new tight-closing sliding door PLANEO AIR SILENT is comparable to a wooden door in terms of sound insulation. In addition, it seals rooms not only against sound, but also against kitchen odours, water vapour and draughts, for example.

Is every Griffwerk sliding door equipped with Softclose?

Please refer to the exact product description of the sliding door system.

Can I lock sliding doors by sensor?

We have developed a special technology for Griffwerk sliding doors: smart2lock: With this, a push of a button is enough to lock or unlock the sliding door. A busy indicator by LED inside and outside shows on the sliding door whether it is locked or unlocked. In addition to long battery life, we have of course made sure that the sliding door can also be unlocked when the batteries are flat: no problem thanks to panic opening and emergency unlocking.

We do not have a sliding door with a motion sensor that opens automatically when you approach.

What types of glass are used for the sliding door?

Toughened safety glass or laminated safety glass. If the sliding door needs to withstand a lot, VSG PRIME DOORS are a good choice. These sliding doors are made of two thermally toughened safety glasses and a tear-resistant film on the inside. If the glass breaks, shards of glass stick to it.

How much space does a sliding door need?

Sliding doors are more space-saving than swinging doors because the swinging range of the door does not have to be considered. Wall-integrated sliding doors save a particularly large amount of space because they disappear into the wall and thus do not take up any space for the door leaf. However, the wall should be thick enough to enclose the sliding door. Exterior sliding doors require a little more space. Tip: You should plan the thickness of the sliding door system along the wall for this.