Prof. Thomas Gerlach

As the academic dean at the university of Pforzheim, Prof. Thomas Gerlach initiated the course of studies Master of Arts in Creative Direction (MACD), which was declared one of the best training locations for design and innovation in 2007 by Business Week, along with Harvard and Stanford.

1983 - 1992, he started his career as the head designer, managing director and European president of frog design, which became world-renowned by its work for Apple, Louis Vuitton, Samsung and Sony. In 1992, he founded via4 Design and has since been consulting for many internationally active companies

In the scope of supplementation of the FRAME hardware system with a glass door solution, we talked to Prof. Thomas Gerlach, among others, about evolution and Darwinism in product design.

Are there still any (design) DIFFERENCES in fittings?

That is a provocative question, and the great similarity actually does stand out. Reasons for this are construction-typical standards and formal archetypes that have become established in the market. In Germany, rosette-grip combinations and jacketed glass lock boxes are dominant. There are few deviations.

Can you call that Darwinism and evolution in hardware design?

Every product goes through evolutionary phases. First, there is a very great diversity of solutions. Over time, the “most capable” approaches become clear. You could call that Darwinism. At the moment, we are experiencing this process in alternative fuels for cars. There was a liquid phase with many ideas, which is now going to slowly morph into a phase with only one or few solutions. The petrol or diesel engine used to be archetypical. We are in the process of a dynamic evolutionary phase.

Is there something like a rule for evolutionary design?

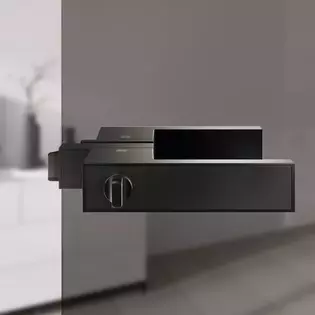

In order to develop products further, we need to wonder which driving forces and ideas we can currently feel in society. We observe a tendency towards the simple and everything that you can call “all in one” simplicity. That means that products are distilled down to a core element. Once, you needed a screen, a keyboard and a computer. Now all you need is a pad. The functions are compressed into one element. With FRAME, we also wondered: How can this be simplified? We finally did without the rosettes and combined it all in a singular shape. To this end, the closing mechanics were integrated into the grip with a patented procedure. The development department at GRIFFWERK supported us greatly in this.

And now you are also offering a glass solution?

Yes, GRIFFWERK expanded its range by glass doors in 2014. Therefore, supplementing the system was a logical step. The technical challenge was even higher this time. The entire closing mechanics had to be reduced to the smallest space. The GRIFFWERK engineers were actually able to solve this and to revolutionarily reduce the lock box’s size. GRIFFWERK therefore no longer calls the result a lock box, but a “glass lock”. It’s just more fitting. I actually think that the product was evolutionarily developed further this way.

Frame - reduction to the next level

There are clear ideas about how a door handle should look. The usual form ensures that the user always knows how to handle it. FRAME appears completely new while still complying with these rules. The patented technique makes it possible to do without roses entirely. The grip shape as such is retained, however. Sufficient on its own, it has a solitary and monumental appearance.

In 2017 this innovative fitting will also be available for glass doors and in graphite black.