Glass doors: for rooms full of light

Glass doors give rooms a bright and inviting atmosphere, making them look more friendly, airy and spacious. Sliding or Hinged doors made of Glass are thus an extremely attractive alternative to traditional doors made of Wood.

Why Glass doors?

- Ensure natural daylight in every living area - thanks to both hinged and Sliding doors

- Greater sense of space and living like in a loft thanks to transparent transitions

- Opaque frosted glass still lets light into the room

- Certified safety with toughened or laminated safety glass (Tempered safety glass / Laminated glass)

- Wide scope for design thanks to motifs you can choose yourself

- Durable, as less susceptible to scratches and wear and tear

- Material without evaporation for better health in the home

- Sound-insulating properties contribute to peace and privacy

- Elegant aesthetics and timeless appearance match a variety of interior styles

- Barrier-free access without threshold allows easy movement through the apartment

- Glass is a sustainable material that is recyclable and has environmentally friendly properties

- The wide variety adapts to one's preferences and styles

- Depending on the model, soundproofing properties ensure less noise

- They create a link between indoor and outdoor areas and expand the living space

- Visual continuity provides a harmonious feeling of space

- Transparency promotes interaction and communication within an apartment or floor

- Sliding doors made of glass can be used to separate small rooms into different living areas

Modern and individual Glass doors from Griffwerk

Whether DIN right or left, laser decorated or matt, whether hinged or Sliding doors: At Griffwerk you are guaranteed to find the right model for your home. From Hygge to Ethno style: For every Living styles we offer the right model and the optimal matching fittings.

Download Glass doors catalog

Our enthusiasm for Glass was sparked in 2014 when we designed our first collection of Glass doors. Glass is a fascinating material because it is made exclusively from Nature or Nature-identical inorganic raw materials. Glass is a sustainable material that is 100 % recyclable. We process this high-quality material using finishing and printing processes. In 2016, we began researching the possibilities of laser technology and incorporating it into our production. We can produce and develop laser doors ourselves at our headquarters in Blaustein in southern Germany. Here is our catalog:

Glass door: home inspired

Glass doors make excellent room doors - whether for the kitchen, living room, hallway or bathroom. Replacing an existing door with a Glass door is very easy. For a glass revolving door, you can even use the existing frame. With Sliding doors made of glass, you can restage transitions between rooms. This looks good and saves space. None of the revolving glass doors or folding doors need to be pivoted. They run along the wall to save space. With the so-called Soft and self-closing mechanism, you treat yourself to additional convenience.

Every model from the GRIFFWERK range is basically available as a glass revolving door or as a Sliding door system.

Even in smaller apartments, previously unused side rooms can be transformed into attractive workrooms with the help of these models.

Glass types for your all glass doors

TSG or LSG - The difference

TSG = toughened safety glass.

Specially heat-treated glass with increased impact and shock resistance. In the event of breakage, small, blunt shards are produced.

- High safety

- High impact and shock resistance

- Blunt-edged shards in case of glass breakage

- Flexible design options

LSG = laminated safety glass

LSG PRIME DOORS consist of two thermally toughened safety glasses and an inner, tear-resistant film. In the event of breakage, the shards adhere to this intermediate layer. LSG PRIME glass also has sound-absorbing properties.

- High safety

- More sound insulation

- Ideal for XL formats

- Matting possible on both sides

- Highest opacity possible

- Rich sound when closing

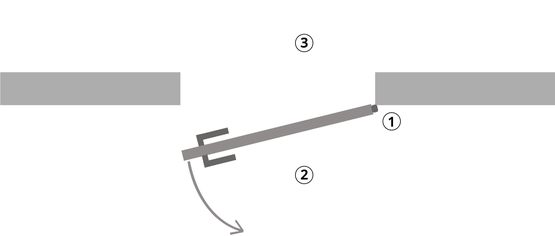

What is the DIN direction for glass doors?

The DIN direction indicates in which direction a door opens. Do you want to find out which DIN direction is the right one for you? Then imagine you are standing in front of the door. It opens towards you. The side on which the hinges of the Hinged door are located - also called the hinge side - determines the DIN direction.

If the hinges are on the right, it is a DIN right-hand door.

If the hinges are on the left, your door is a DIN left door.

What is the tape side and the tape opposite side?

Door hinges connect a door to the door frame and at the same time allow it to rotate. The hinge side (2) is the side on which the door hinges (1) are located. The opposite hinge side (3) refers to the side opposite the door hinges.

Glass door finishing techniques: technology and advantages at a glance

Glass door with digital printing

In the digital printing process, a motif is printed on the interior security film of an all-glass door made of laminated safety glass.

With transparent films, the design can be seen from both sides - mirror-inverted on the back of the Glass door. However, the film can also be matt or white, for example, which makes printed photos and motifs stand out clearly.

Advantages digital printing

- None fading of the Color thanks to protection from NL radiation by bonding of film and glass panes

- High resolution

- Radiant and high light fastness of colors behind the glass

- Transparency and translucency (light transmission)

Glass doors with screen printing

For screen printing on the glass door, ceramic paint is permanently baked into the glass during the manufacturing process of the toughened safety glass.

The screen printing process additionally seals the glass surface with the application of motifs. The finished glass door has a closed, smooth surface that is extra scratch-resistant.

Advantages screen printing

- Very high scratch resistance

- Abrasion and weather resistant

- Hard-wearing

- Easy to clean

- Precise printing of motifs

Glass door with laser technology

For finishing with laser technology, laser beams are bundled and focused with millimeter precision. The laser penetrates 0.3 mm deep into the surface of the glass. The spot where the laser hits is melted for a short time. Safety glass is not negatively affected. Precisely controlled laser beams create images on the glass using a series of dots.

Advantages laser technology

- Stunning clarity and sharpness

- High luminosity and beautiful lighting effect

- Noble and stylish

- Individual ideas can be easily realized

Fascination Laser Technology

Special lasers engrave filigree Lines into the glass surface. Point by point and precisely controllable, detailed images, patterns and lettering as well as finely graduated gradients can be transferred to the Glass. Our laser places microscopically small pixels next to each other for this purpose, so that photorealistic results can be achieved. The recessed engravings change the reflection of light. Lasered Glass doors remain transparent. The TWO SIDES option with satin finish on the back provides more privacy.

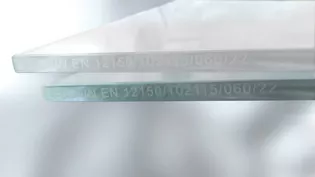

Laser-engraved glass doors from Griffwerk meet ESG standard

GRIFFWERK offers tested safety for lasered glass doors made of single-pane safety glass ("TSG glass"). According to the German Institute for Building Technology (DIBT), the laser technology applied by GRIFFWERK fulfils all requirements. Since then GRIFFWERK is allowed to mark all glass doors with the TSG test stamp.

The stamp contains the number of the standard (DIN EN 12150) and is placed on the edge of the glass on the hinge side. ESG is available from GRIFFWERK as green glass or elegant white glass PURE WHITE by GRIFFWERK. Both types of glass also meet the ESG standard when lasered.

Thanks to laser decor: glass doors to suit your individual taste

We realize your ideas

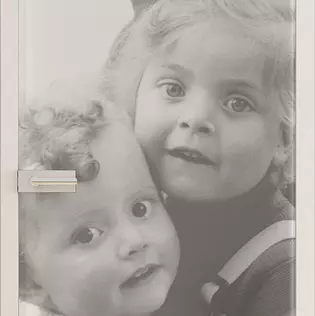

Have your favorite quote, your children's names or any text lasered onto your Glass door! Choose the size, format and placement according to your ideas.

If you are interested, please ask your

Your favorite picture as a laser engraving?

Whether a family photo or memories of an unforgettable moment - create your own design.

Talk to your specialist dealer!

Two sides of a Glass door - Two Sides

Our extensive range is also available in the transparent "TWO SIDES" variant, which is processed on both sides: one side is lasered, the other is flat Satin frosted. This allows you to choose from a variety of favorite designs for your all-glass door while getting more privacy with the frosted glass.

By the way, our TWO SIDES option has nothing to do with the difference in DIN Direction - that is, whether you are dealing with "DIN Left" or "DIN Right" doors. If hinges and hinges are mounted on the left, they are "DIN-left" doors. If they are mounted on the right, they are "DIN right" doors.

What is Laser One Side?

- ONE SIDE means one-sided processing of the all-glass door with laser technology.

- Here a clear glass blank is used

- The transparency of the door is maintained

- Depending on the incidence of light, the lasered area scores with its high luminosity

- One Side is very noble and stylish

What is Laser TWO SIDE?

- With TWO SIDE, the manufacturer processes the all-glass door on both sides

- The glass door blank has a full-surface silk-screen print on the back side (matted on the back side)

- The laser decor is on the front side

- The translucency is in the foreground here

- Brighter rooms despite guaranteed privacy

One look. For the whole apartment.

If you decide on something special, you don't want to have to make any compromises. With our range you can equip your entire living room with handles in your desired colour throughout: from cashmere grey to stainless steel to brass look - from door to window.

How do I clean my Glass door?

When cleaning your interior glass, it is sufficient to clean it with warm water. Use a sponge or a soft, lint-free cloth for this purpose. Clean over a large area, not selectively.

If there are residues, such as fingerprints, you can also use commercially available glass cleaners (foam cleaners). Please refrain from using corrosive, acidic or alkaline cleaning agents, as these can cause scratches. Excess water can simply be wiped dry with a microfiber cloth. If water acts on the Glass door over a longer period of time, stubborn lime residues can form.

In the case of Laminated glass doors, make sure that the edge seal does not come into contact with water, otherwise moisture and the cleaning agent can penetrate the laminate.

For Satin frosted and lasered surfaces

To avoid abrasion, do not apply too much pressure here. To prevent cloud formation, rub your glass door dry over a large area with a microfiber cloth. None use paper or cellulose cloths. They cause too much abrasion.

For screen printed glass

Screen printed models are softer than pure glass and therefore more sensitive to mechanical cleaning agents. In addition, they must not come into contact with acids, as these can attack the printed image.

Attention

Please do not use any scratching tools, razor blades or scrapers. They can leave visible and irreparable scratch marks.

Glass doors: suitable for any interior

From iconic Bauhaus to casual boho style, the all-glass door reveals a wide range of styles. Modern living is characterized by clean lines and minimalist flair, while boho style is highlighted by etched glass with playful patterns and earthy tones. Scandinavian living aesthetics are reflected by bright transparency and simple frames, while the country house style focuses on rustic elegance with subtle embellishments. Followers of the hygge concept are attracted to warm, cozy glass, while the art deco style shines with elegant patterns and sophisticated glass gloss. Glass doors convey style diversity in a unique way, be it minimalism or opulence.

7 Tips for more privacy for Glass doors

Glass doors are not only aesthetically pleasing, but can also provide security and privacy when designed properly. Here are some practical tips on how to make your Glass doors more secure and intimate:

- Privacy films: use frosted glass or privacy films to frost the glass. These films are available in a variety of designs and provide adequate privacy while allowing natural light to continue to stream in.

- Choose glass types: Opt for etched or textured glass that diffuses light but prevents clear sight lines. This is an ideal option for areas like bathrooms or bedrooms.

- Pair with curtains: Install curtains or blinds that can be closed when needed for protection. These can be stylish and complement the ambiance of the room.

- Focus on positioning: Place Glass doors in areas where privacy is less important, such as between living and dining areas, to maximize natural light.

- Add texture: Choose Glass doors with structured or colored elements to add visual interest while maintaining privacy.

- Smart Lighting: Use cleverly placed lighting to brighten areas around Glass doors and create distractions from the glass surface.

- Multiple Glazing: In areas where security is a greater concern, the use of double-glazed or laminated glass can increase stability and safety.

Glass doors: FAQ

What does a glass door cost?

You can even find reasonably priced glass doors from Griffwerk for less than 150 euros. Our most luxurious models are priced at more than 1000 euros.

Which doors offer more sound insulation?

The more mass a door has, the more sound-absorbing the material is and the better the door seals, the better it protects against noise. Wooden doors are thicker but not generally more sound-absorbent than glass doors. With sliding doors, it is important to use a suitable sealing system. It closes the open gap between the door leaf and the wall.

Can a glass door be installed in a normal frame?

Yes. Existing frames for wooden doors can also be used for glass doors. When installing a glass door, please note whether 2-part hinges or 3-part hinges are to be used. To match the respective hinges, only the frame section needs to be replaced, readjusted and screwed tight. Then just hang it in place. That's it.

How soundproof is glass?

Glass can generally repel sound well and thus prevent transmission. Special window panes are predestined for even the most demanding sound insulation tasks. They are made of several panes of different thicknesses (so-called asymmetrical construction) and are connected by an elastic inner film. LSG doors also consist of several layers and an elastic inner film. They therefore have good sound insulation properties and are more suitable than, for example, simple toughened glass doors.

Why white glass for my glass door?

White glass has a special lighting effect, allows a particularly large amount of light into the room and shows off decors to brilliant effect. For the production of white glass PURE WHITE by GRIFFWERK, the iron oxide content is reduced to minimise the green cast.

Are glass doors normed?

There are so-called norm doors for glass doors. These have standard dimensions so that they can be hung in various door frames. These are the widths: 709 mm, 834 mm and 959 mm, in combination with the heights 1972 mm or 2097 mm.

Is it possible to install a Glass door without a frame?

Glass door without frame can be installed in a doorway in certain cases, but it depends on the type of doorway. Sliding doors and Double action doors are often better suited for installation without a frame, as they require less framing. Hinged doors can be more difficult to achieve a stable installation Without a frame. Regardless of Door type, it is important to ensure that the door is properly and securely fastened and meets local building codes. Professional help is often advisable to ensure a safe installation.

How can glass doors be shortened?

Not at all. A glass door made of safety glass cannot be shortened or cut. Doors made of safety glass include TSG (toughened safety glass) or LSG (laminated safety glass) doors. The manufacturing process of a safety glass door hardens the glass. Due to the tempering of the glass, the glass door would shatter if it were shortened.

What should I consider when choosing handles for Sliding doors?

When choosing Sliding door handles, there are several important aspects to consider to ensure that they are not only functional, but also aesthetically and ergonomically suitable. Here are some Spots you should consider:

- Functionality: the Sliding door handle should be easy to grip and operate. Not only should it feel good in your hand, but it should also provide adequate leverage to move the door panel effortlessly.

- Material and Quality: Sliding door handles are available in different materials such as Stainless steel, Aluminum, Plastic or Wood. Choose a high-quality material that is durable and sturdy to withstand daily use.

- Ergonomics: the handle should be designed to fit comfortably and securely in your hand. An ergonomic design allows for ease of use, especially if the door is used frequently.

- Style and aesthetics: the Sliding door handle contributes to the overall aesthetic of the room. Choose a handle that matches the style and decor of the room. There are a variety of designs, from modern and minimalist to traditional and decorative.

- Size and proportions: Make sure the handle is the right size and proportion so it doesn't look oversized or too small in relation to the size of the door.

- Mounting: consider how the handle will be mounted on the Sliding door. A handle can be mounted on the front or back of the door panel, depending on the desired aesthetic effect.

- Accessibility: if necessary, choose a Sliding door handle that is barrier-free and can be easily reached and operated by people with limited mobility.

- Durability and maintenance: consider the maintenance requirements of the material you choose. Some materials require more care than others to maintain their luster and quality over time.

- Price: Sliding door handles vary widely in price and quality. Set yourself a budget and look for a handle that meets both your needs and your budget.

- Additional features: Some Sliding door handles come with additional features like locking mechanisms or lock cases. If you need such features, make sure the handle meets those requirements.

- Installation: Make sure the handle is easy to install or can be properly installed by professionals to ensure safe use.

Remember that the Sliding door handle is not only a functional element, but also contributes to the aesthetics and usability of the room. It is important to make a careful selection to ensure that the handle meets the requirements and style of the project.

What is a whisper latch?

A whisper latch is a door latch that has been partially coated with plastic. The plastic dampens the impact of the metal latch in the lock. Doors can thus be closed "whisper quietly". Whisper latches are available for door handles for wooden doors as well as for glass lock cases on all-glass doors.

Which frame for a glass door?

For glass doors, you can use your existing frame.

How soundproof are glass doors?

Anyone who wants sound insulation can opt for glass doors. In principle, all-glass revolving doors can provide sound insulation up to class 2 (SK2 according to DIN 4109) - i.e. offer the same sound insulation as wooden doors. This is mainly because glass throws sound back into the room rather than letting it through. The reason is simple: glass has no cavities and does not vibrate easily, which would amplify sound.

Tip: A door leaf made of LSG glass, unlike simple single-pane safety glass (TSG), has sound-absorbing properties. The sound insulation film is softer and decouples the panes. As a result, the sound is better insulated.

A special feature of glass doors: they need a floor gap so that dirt particles such as small stones do not damage the glass. This minor disadvantage is easy to compensate for: with sound-absorbing materials in the rooms - such as deep pile carpets or curtains.

Can you replace a wooden door with a glass door?

Basically, it is possible to keep the frame of a wooden door and only replace the door leaf. In this case, you should first measure whether your frame corresponds to a standard dimension. To do this, measure the rebate dimensions. To do this, take the distance between the inner edges of the rebate cladding in width and the distance between the lower edge of the rebate cladding to the upper edge of the floor covering in height. If the rebate dimensions are standardised, you can choose your new glass door directly and install it in the frame.

If you need special dimensions, you can either have a new frame fitted so that you can use standard sizes. As a cost-effective alternative, we recommend having the glass door leaf custom-cut.

Also bear in mind that the glass door needs to be drilled. This cannot be done on site - a professional should drill the glass door before installation. The door fittings are then fitted in the resulting recesses.

Furthermore, you should bear in mind that not every door hinge will work with the new glass door. However, you can replace these without any problems.